SBM's dolomite grinding mill stands out in terms of competitive pricing due to its status as a grinding mill machine manufacturer. Being a manufacturer allows SBM to supply machines at lower prices compared to other brands. This cost advantage, combined with quality and after-sales service, contributes to SBM's appeal to customers.

Recent advancements in dolomite grinding technology may include improvements in grinding efficiency, energy consumption, and the development of more specialized grinding mills. Continuous research and innovation contribute to enhancing the overall performance and capabilities of dolomite grinding mills.

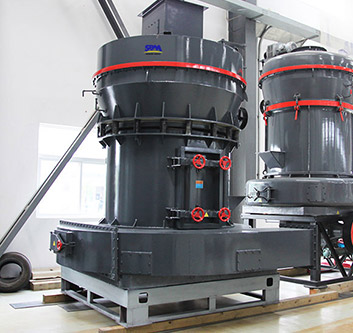

The dolomite grinding mill contributes to environmental protection through its closed system, preventing material leakage. Safety and reliability are ensured by the rigorous mill design, eliminating problems like bolt shedding and rapid wear. The absence of rolling bearings or screws in the grinding cavity further enhances safety.

The dolomite grinding mill boasts high efficiency, with double the capacity of jet mill and reduced energy consumption by 30%. The ring and roller have a long lifecycle, ensuring durability. Its design eliminates problems like bolts shedding, offering high safety. The adjustable fineness (325-2500 mesh) caters to diverse needs, and its closed system promotes environmental friendliness.

The Gypsum Powder Grinding Mill shares similarities in structure with the Dolomite Grinding Mill, involving a mill body, blower fan, and cyclone container. However, differences lie in their applications and specific advantages. While both offer high efficiency and environmental friendliness, the choice between them depends on the material being processed.

The dolomite grinding mill allows users to adjust the fineness between 325 meshes and 2500 mesh, offering flexibility in meeting specific requirements. This adjustability benefits users by allowing them to tailor the grinding process to produce dolomite powder with the desired particle size.

Dolomite powder grinding, a crucial process in various industries, requires specialized equipment to achieve the desired particle size and quality. To grind dolomite into fine powder, specialized equipment such as grinding mills is essential. Among the options are the Raymond mill, vertical roller mill, and ultra-fine grinding mill. The ultra-fine grinding mill stands out for its adjustable fineness (325-2500 mesh), high efficiency, low energy consumption, and large production capacity. The vertical roller mill, utilizing rollers to grind materials, offers flexibility in adjusting the fineness (80-400 mesh) with advantages in efficiency and compact design.

To meet diverse needs, various types of grinding mills are employed, each boasting unique features. The ultra-fine grinding mill, with its ability to finely adjust particle sizes within the range of 325-2500 mesh, stands out for its high efficiency, low energy consumption, and substantial production capacity. Additionally, the vertical roller mill, with a fineness range of 80-400 mesh, offers advantages such as high grinding efficiency, a compact footprint, and low power consumption, making it ideal for customizable dolomite powder grinding.

The transformation of dolomite into fine powder involves a well-coordinated production line. This includes essential components such as a hammer crusher, bucket elevator, storage hopper, vibrating feeder, main unit, inverter classifier, cyclone collector, pulse deduster system, high-pressure positive blower, air compressors, and electrical control systems. This comprehensive setup ensures efficient and precise dolomite powder production.

The operational principle of the dolomite grinding mill revolves around systematic processes. Grinding rollers, driven by centrifugal force, crush and grind materials at the edge of the turnplate. A high-pressure air blower facilitates a constant airflow within the mill, directing qualified particles to the powder collector through the classifier. Unqualified particles are returned for regrinding, resulting in a refined final product.

The latest technological enhancements in dolomite grinding mills highlight several key advantages. These include significantly improved efficiency, with a capacity twice that of traditional mills and a 30% reduction in energy consumption. Moreover, the forged ring and roller construction ensures a long lifecycle of 2-5 years, minimizing maintenance issues. The absence of rolling bearings or screws in the grinding cavity further enhances safety and reliability. Additionally, the flexibility in fineness adjustment, ranging from 325 meshes to 2500 mesh, and the overall environmentally friendly design, make these mills integral to modern mineral processing practices.

The dolomite grinding mill's closed system prevents environmental pollution by containing the materials and ensuring efficient powder collection. Its green design aligns with environmental protection standards, making it an ideal choice for eco-conscious operations.

The micro powder grinding mill, including Raymond mill, ultra-fine grinding mill, and vertical roller mill, specializes in grinding materials to sizes exceeding 200 mesh. Each mill has unique characteristics, with Raymond mill suitable for 50-500 mesh powder, ultra-fine grinding mill for 300-2500 mesh, and vertical roller mill for 300-3000 mesh, catering to various micro powder grinding needs.

The capacity range (1-45 t/h) of dolomite powder making machines is influenced by factors such as machine model, design, and motor power. Users can control the capacity based on demand by selecting the appropriate machine model and adjusting operational parameters.